Related Resources: hardware

Groove Design for Metric ISO Size O-Rings per. ISO 3601-2

Fluids, Piping and Hydraulic Design Data

Groove Design for Metric ISO Size O-Rings per. ISO 3601-2

An initial compression (squeeze) of the O-Ring in the groove is essential to ensure its function as a primary or secondary sealing element. It serves to:

- Achieve the initial sealing capability

- Bridge production tolerances

- Assure defined frictional forces

- Compensate for the compression set

- Compensate for wear

Depending on the application, the following values apply

for the initial squeeze as a proportion of the cross section

(d2):

Dynamic applications: 6 to 20%

Static applications: 15 to 30%

The design of the grooves can be based on the guide values for the initial squeeze shown in the diagrams in Figure 1 and 2. These take into account the relationship between loads and cross sections according to ISO 3601-2 (version 1987).

Figure 1, Permissible range of initial squeeze as a

function of cross section, radial dynamic

Figure 2, Permissible range of Initial squeeze as a

function of cross section, radial static and axial

Shaft and bores

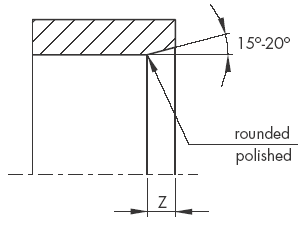

Figure 3, Lead-in chamfers for bores, tubes

Figure 4 Lead-in chamfers for shafts, rods

Table 1, Lead Lead-in Chamfers

Lead-in chamfers length Z min. |

O-Ring cross section d2 |

|

15° |

20° |

|

2.5 |

2.0 |

up to 1.78 1.80 |

3.5 |

2.5 |

up to 2.62 2.65 |

4.5 |

3.5 |

up to 3.53 3.55 |

5.0 |

4.0 |

up to 5.33 5.30 |

6.0 |

4.5 |

up to 7.00 |

The surface roughness of a lead-in chamfer is:

RZ ≤ 6.3 µm

Ra ≤ 0.8 µm

The tolerances given in table XV and the maximum permissible radial clearance S (extrusion gap) given in the table XII must be maintained.

If the clearance is too large, there is a risk of seal extrusion which can result in the destruction of the O-Ring

Figure 5 Radial clearance “S“

Figure 6, O-Ring installation recommendations

This Chart Calculator Specifies Groove design for o-ring sizes ranging from 0.5 to 12.00 mm per. ISO 3601-2. (Premium Membership required)

Preview: Groove design for o-ring sizes table calculator

1) When using Back-up Rings the groove is to be widened by the corresponding Back-up Ring thickness (b2: one Back-up Ring, b3: two Back-up Rings).

2) If a Back-up Ring is used the recommended radius r1 should

always be r1= 0.25 ±0.2mm.

Reference:

ISO 3601-2, (Version 1987)

Related:

- Analysis of large-sized O-rings used in pressure chambers

- Mechanical Seal Balance Ratio Formula and Calculator

- Specification for Rubber Gaskets Free Membership Required

- Rubber Molding Design Guidelines and Review

- Poppet Seal Gasket Oring Operating Life and Reliability Equations and Calculator

- O-Ring, Design Considerations General

- O-Ring Installation, Design & Specification Gland (Groove) Sizes Static Cylindrical Applications

- O-Ring Installation, Design & Specification Gland (Groove) Sizes Static Flange Application

- O-Ring Installation Design & Specification For Dynamic / Reciprocating Applications

- O-Ring Installation Compressive Load vs Hardness Chart .070 Diameter ORing

- O-Ring Installation Compressive Load vs Hardness Chart .103 Diameter ORing

- O-Ring Installation Compressive Load vs Hardness Chart .139 Diameter ORing

- O-Ring Installation Compressive Load vs Hardness Chart .210 Diameter ORing

- O-Ring Installation Compressive Load vs Hardness Chart .275 Diameter ORing