Related Resources: calculators

Pipe Straight Pipe or Large Bends Stress Calculator and Equations

Hydraulic & Pneumatics

Fluids Flow Design and Engineering

The nominal bending stress in a straight pipe or large radius bends due to weight or other external load calculator.

Preview: Pipe Bending Straight Pipe or Large Bends Stress Calculator

Pipe Bending Stress due to Weight or other External Loads is:

Eq. 1SB = M / Z

The nominal bending stress in fittings and components due to weight or other external loads is:

Eq. 2

SB = MR / Z

Resultant intensified moment across the fitting or component. The resultant moment shall be calculated as:

Eq. 3

MR = [ ( 0.75 ii Mi )2 + ( 0.75 io Mo )2 + Mt 2 ]1/2

Eq. 4

Z = 1 / I

Eq. 5 (area moment of inertia pipe)

I = π ( D4 - d4 ) / 64

Eq. 6 (section modulus pipe)

Z = π ( D4 - d4 ) / ( 32 D )

Where

M = the bending moment across the pipe cross section, lb-in, (N-m)

Z = The pipe section modulus, in3 (m3)

ii = in-plane stress intensification factor

io = out-of-plane stress intensification factor

Mi = in-plane bending moment, lb-in. (N-m)

Mo =out-of-plane bending moment, lb-in. (N-m)

Mt = torsional moment, lb-in (N-m)

D = outer diameter, in (m)

d = inner diameter, in (m)

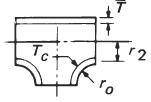

Figure 1, Pipe Data

If a section of pipe can operate either warmer or colder than the installed temperature, both conditions to T2 may need to be examined.

Table 1, Stress Intensification Factor, i per. ASME B31.8

Description |

Out of Plane io |

In-Plane ii |

Sketch |

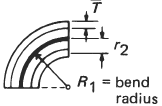

Welding elbow or pipe bend |

0.75 / h2/3 |

0.90 / h2/3 |

|

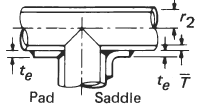

Welding tee per |

- |

3/4 io + 1/4 |

|

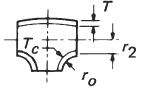

Reinforced fabricated tee with pad or saddle |

- |

3/4 io + 1/4 |

|

Unreinforced fabricated tee |

- |

3/4 io + 1/4 |

|

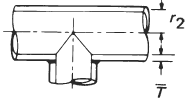

Extruded outlet ro ≥ d / 8 Tc < 1.5 |

- |

3/4 io + 1/4 |

|

Source:

ASME B31.9, Gas Transmission and Distribution Systems

Related

- Pipe Bends Minimum Wall Thickness Calculator per. ASME B31.3

- L Pipe Bend Guided Cantilever Beam Equation and Calculator

- Pipe Stress Due to Sustained Loads Formulae and Calculator

- Pipe Thread Installation Torque Table Chart

- Pipe Support Spacing For Deflection Control Design Calculator

- Allowable Stresses for Pipe and Tube B36.10M

- Thermal Expansion or Contraction of Piping per. ASME B31.8

- Steel Pipe Clamps Stress and Friction Capacity Analysis

- Pressure Vessel Design Formula and Calculators Resources

- Pressure Vessel Pipe Stress Longitudinal Stress (Circumferential Joint) Calculator

- Pipe Thread Installation Torque Table Chart

- Copper Tubing Size Chart ASTM B-88

- Standard Pipe Schedules and Sizes Chart Table Data

- Schedule 80 Steel Pipe Sizes & Dimensions ANSI American National Standard Schedule 80 Welded and Seamless Steel Pipe.

- Schedule 40 Plastic PVC, CPVC Pipe Sizes & Dimensions PVC, CPVC and other Schedule 40 Plastic Pipe.

- Schedule 80 Plastic PVC, CPVC Pipe Sizes & Dimensions American National Standard Schedule 80 Welded and Seamless Steel Pipe.