Related Resources: motors

Motor Shaft Load Due to Belt Loading Equations and Calculator

Electric Motors, Generators and Drives

V-Belt Design and Engineering

Electric Motor Shaft Load Due to Belt Loading Equations and Calculator

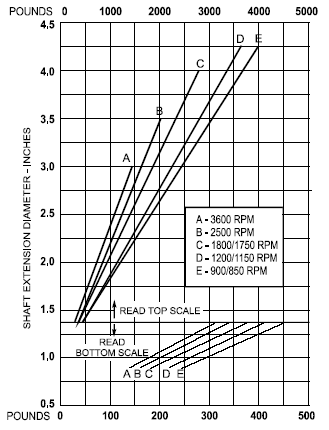

The most common application that results in an overhung load on the shaft is a V-belt drive. V-belts are friction devices and depend on tension in the belts to prevent slipping. The following equation may be used to calculate the shaft load due to belt pull. Should the load exceed the values shown in Figure 1 (see bottom of webpage) the load should be reduced by reducing the belt tension, which may cause belt slippage, or by increasing the sheave diameter.

ALL calculators require a Premium Membership

Preview: Electric Motor Shaft Load Due to Belt Loading Calculator

Where:

LB = Shaft overhung load due to belt tension, lb

NB = Number of belts

PA = Force required to deflect one belt 1/64 inch per inch of span, lbs

Y = 2 (favg) ( 1/64)2 where f is a strain constant based on the type and section of belt. Available from belt manufacturer

M = 0.9 m where m is the weight per unit length, lb/in., of the type and section of belt. Available from belt manufacturer.

V = Belt speed, ft/min

Fv = Vector sum correction factor. Corrects tight side and slack side tension vectors for unequal driver/driven sheave diameter. Assumes 5:1 tension ratio. Available in belt manufacturer’s catalogs.

The calculation should be made after all parameters are known and PA measured on the actual installation. Pre-installation calculations may be made by calculating the belt static tension required by the application and the value of PA necessary to attain that tension.

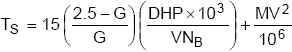

Where:

TS = Belt static tension required by the application, lb

G = Arc of contact correction factor. Available from belt manufacturer

DHP = Drive horsepower, belt service factor x motor hp

After calcualting the required belt static tension, the minimum value of PA to attain the required static tension is:

![]()

Calculated value may now be used in the first equation for pre-installation application calculations. In actual practice, a value up to 50% greater than PA (MIN) is sometimes used. In this case, the higher value should be used in the first equation.

Figure 1

Note:

Arc of Contact correction Pitch or Outside Datum, Pitch, or Factor = Pitch or Outside Diameter = Datum, Pitch, or Outside Diameter

Reference: NEMA MG 1-2009