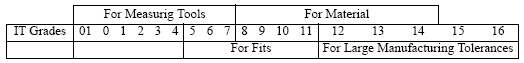

International Tolerance (IT) Grades Table Chart ISO 286-1

Mechanical Tolerance Standards Menu

International Tolerance (IT) Grades table reference ISO 286. This mechanical tolerance grade specifies tolerances with associated manufacturing processes for a given dimension.

Related: International Tolerance Grades formulas:

Application:

Most manufacturing processes have an IT Grade designated for specification. IT grades provide guidance for typical manufacturing process capability or how precise one can except manufacture of a particular features or features.

When designing a part and specifying mechanical tolerances, engineering or design will determine size and location for a particular feature. Using the designated International Tolerance Grade formula, the IT Grade required or typical to produce the part feature is assigned. For example, plastic injection molding is determined to have an IT Grade of 13 and a part needs an IT Grade of 5, engineering and design should consider an alternative and more capable manufacturing process to produce the part and feature.

Nominal mm |

Standard Tolerance Grades µm |

|||||||

|---|---|---|---|---|---|---|---|---|

IT01 |

IT0 |

IT1 |

IT2 |

IT3 |

IT4 |

IT5 |

||

Above |

Up to and including |

µm |

||||||

— |

3 |

0,3 |

0,5 |

0,8 |

1,2 |

2 |

3 |

4 |

3 |

6 |

0,4 |

0,6 |

1 |

1,5 |

2,5 |

4 |

5 |

6 |

10 |

0,4 |

0,6 |

1 |

1,5 |

2,5 |

4 |

6 |

10 |

18 |

0,5 |

0,8 |

1,2 |

2 |

3 |

5 |

8 |

18 |

30 |

0,6 |

1 |

1,5 |

2,5 |

4 |

6 |

9 |

30 |

50 |

0,6 |

1 |

1,5 |

2,5 |

4 |

7 |

11 |

50 |

80 |

0,8 |

1,2 |

2 |

3 |

5 |

8 |

13 |

80 |

120 |

1 |

1,5 |

2,5 |

4 |

6 |

10 |

15 |

120 |

180 |

1,2 |

2 |

3,5 |

5 |

8 |

12 |

18 |

180 |

250 |

2 |

3 |

4,5 |

7 |

10 |

14 |

20 |

250 |

315 |

2,5 |

4 |

6 |

8 |

12 |

16 |

23 |

315 |

400 |

3 |

5 |

7 |

9 |

13 |

18 |

25 |

400 |

500 |

4 |

6 |

8 |

10 |

15 |

20 |

27 |

500 |

630 |

- |

- |

9 |

11 |

16 |

22 |

32 |

630 |

800 |

- |

- |

10 |

13 |

18 |

25 |

36 |

800 |

1 000 |

- |

- |

11 |

15 |

21 |

28 |

40 |

1 000 |

1 250 |

- |

- |

13 |

18 |

24 |

33 |

47 |

1 250 |

1 600 |

- |

- |

15 |

21 |

29 |

39 |

55 |

1 600 |

2 000 |

- |

- |

18 |

25 |

35 |

46 |

65 |

2 000 |

2 500 |

- |

- |

22 |

30 |

41 |

55 |

78 |

2 500 |

3 150 |

- |

- |

26 |

36 |

50 |

68 |

96 |

Nominal mm |

Standard Tolerance Grades µm | ||||||

|---|---|---|---|---|---|---|---|

IT6 |

IT7 |

IT8 |

IT9 |

IT10 |

IT11 |

||

Above |

Up to and including |

µm | |||||

— |

3 |

6 |

10 |

14 |

25 |

40 |

60 |

3 |

6 |

8 |

12 |

18 |

30 |

48 |

75 |

6 |

10 |

9 |

15 |

22 |

36 |

58 |

90 |

10 |

18 |

11 |

18 |

27 |

43 |

70 |

110 |

18 |

30 |

13 |

21 |

33 |

52 |

84 |

130 |

30 |

50 |

16 |

25 |

39 |

62 |

100 |

160 |

50 |

80 |

19 |

30 |

46 |

74 |

120 |

190 |

80 |

120 |

22 |

35 |

54 |

87 |

140 |

220 |

120 |

180 |

25 |

40 |

63 |

100 |

160 |

250 |

180 |

250 |

29 |

46 |

72 |

115 |

185 |

290 |

250 |

315 |

32 |

52 |

81 |

130 |

210 |

320 |

315 |

400 |

36 |

57 |

89 |

140 |

230 |

360 |

400 |

500 |

40 |

63 |

97 |

155 |

250 |

400 |

500 |

630 |

44 |

70 |

110 |

175 |

280 |

440 |

630 |

800 |

50 |

80 |

125 |

200 |

320 |

500 |

800 |

1 000 |

56 |

90 |

140 |

230 |

360 |

560 |

1 000 |

1 250 |

66 |

105 |

165 |

260 |

420 |

660 |

1 250 |

1 600 |

78 |

125 |

195 |

310 |

500 |

780 |

1 600 |

2 000 |

92 |

150 |

230 |

370 |

600 |

920 |

2 000 |

2 500 |

110 |

175 |

280 |

440 |

700 |

1 100 |

2 500 |

3 150 |

135 |

210 |

330 |

540 |

860 |

1 350 |

Nominal mm |

Standard Tolerance Grades mm |

|||||||

|---|---|---|---|---|---|---|---|---|

IT12 |

IT13 |

IT14 |

IT15 |

IT16 |

IT117 |

IT18 |

||

Above |

Up to and including |

mm |

||||||

— |

3 |

0,1 |

0,14 |

0,25 |

0,4 |

0,6 |

1 |

1,4 |

3 |

6 |

0,12 |

0,18 |

0,3 |

0,48 |

0,75 |

1,2 |

1,8 |

6 |

10 |

0,15 |

0,22 |

0,36 |

0,58 |

0,9 |

1,5 |

2,2 |

10 |

18 |

0,18 |

0,27 |

0,43 |

0,7 |

1,1 |

1,8 |

2,7 |

18 |

30 |

0,21 |

0,33 |

0,52 |

0,84 |

1,3 |

2,1 |

3,3 |

30 |

50 |

0,25 |

0,39 |

0,62 |

1 |

1,6 |

2,5 |

3,9 |

50 |

80 |

0,3 |

0,46 |

0,74 |

1,2 |

1,9 |

3 |

4,6 |

80 |

120 |

0,35 |

0,54 |

0,87 |

1,4 |

2,2 |

3,5 |

5,4 |

120 |

180 |

0,4 |

0,63 |

1 |

1,6 |

2,5 |

4 |

6,3 |

180 |

250 |

0,46 |

0,72 |

1,15 |

1,85 |

2,9 |

4,6 |

7,2 |

250 |

315 |

0,52 |

0,81 |

1,3 |

2,1 |

3,2 |

5,2 |

8,1 |

315 |

400 |

0,57 |

0,89 |

1,4 |

2,3 |

3,6 |

5,7 |

8,9 |

400 |

500 |

0,63 |

0,97 |

1,55 |

2,5 |

4 |

6,3 |

9,7 |

500 |

630 |

0,7 |

1,1 |

1,75 |

2,8 |

4,4 |

7 |

11 |

630 |

800 |

0,8 |

1,25 |

2 |

3,2 |

5 |

8 |

12,5 |

800 |

1 000 |

0,9 |

1,4 |

2,3 |

3,6 |

5,6 |

9 |

14 |

1 000 |

1 250 |

1,05 |

1,65 |

2,6 |

4,2 |

6,6 |

10,5 |

16,5 |

1 250 |

1 600 |

1,25 |

1,95 |

3,1 |

5 |

7,8 |

12,5 |

19,5 |

1 600 |

2 000 |

1,5 |

2,3 |

3,7 |

6 |

9,2 |

15 |

23 |

2 000 |

2 500 |

1,75 |

2,8 |

4,4 |

7 |

11 |

17,5 |

28 |

2 500 |

3 150 |

2,1 |

3,3 |

5,4 |

8,6 |

13,5 |

21 |

33 |

1) Values for standard tolerance grades IT01 and IT0 for basic sizes less than or equal to 500 mm are given in IS0 286-1, annex A, table 5.

2) Values for standard tolerance grades IT1 to IT5 (incl.) for basic sizes over 500 mm are included for experimental use.

3) Standard tolerance grades IT14 to IT18 (incl.) shall not be used for basic sizes less than or equal to 1 mm.

Related Resources:

- Gage Tolerance Calculator ASME B89.1.5 Pin and Ring Gauges

- ISO Tolerances For Fasteners

- Gauge Blocks Tolerances Specifications Table DIN 861

- General Tolerances Shaft - Holes Fits

- GD&T Geometric Dimensioning Tolerancing Basics Training

- GD&T Geometric Dimensioning Tolerancing Intermediate Training

- GDT ASME Y14.5-2009 Applications Training

- G&T Geometric Tolerancing ISO 1101 Training

- Online GD&T Fundamentals Training

Reference:

ISO - International Organization for Standardization ISO 286-1 - 2010(E)