Two Phase Fluid Flow Review

Fluid Flow Table of Contents

Hydraulic and Pneumatic Knowledge

Two Phase Fluid Flow Review

In fluid mechanics , two-phase flow occurs in a system containing gas and liquid with a meniscus separating the two phases . Two-phase flow is a particular example of multiphase flow .

All of the fluid flow relationships discussed previously are for the flow of a single phase of fluid whether liquid or vapor. At certain important locations in fluid flow systems the simultaneous flow of liquid water and steam occurs, known as two-phase flow. These simple relationships used for analyzing single-phase flow are insufficient for analyzing two-phase flow.

There are several techniques used to predict the head loss due to fluid friction for two-phase flow. Two-phase flow friction is greater than single-phase friction for the same conduit dimensions and mass flow rate. The difference appears to be a function of the type of flow and results from increased flow speeds. Two-phase friction losses are experimentally determined by measuring pressure drops across different piping elements. The two-phase losses are generally related to single-phase losses through the same elements.

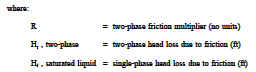

One accepted technique for determining the two-phase friction loss based on the single-phase loss involves the two-phase friction multiplier (R), which is defined as the ratio of the two-phase head loss divided by the head loss evaluated using saturated liquid properties.

The friction multiplier (R) has been found to be much higher at lower pressures than at higher pressures. The two-phase head loss can be many times greater than the single-phase head loss.

Although a wide range of names has been used for two-phase flow patterns, we shall define only three types of flow. The flow patterns to be used are defined as follows:

1. Bubbly flow: there is dispersion of vapor bubbles in a continuum of liquid.

2. Slug flow: in bubbly flow, the bubbles grow by coalescence and ultimately become of the same order of diameter as the tube. This generates the typical bullet-shaped bubbles that are characteristic of the slug-flow regime.

3. Annular flow: the liquid is now distributed between a liquid film flowing up the wall and a dispersion of droplets flowing in the vapor core of the flow.