Flat Belt Length and Pulley Center Distance Calculation

V and Flat Belt Design Guide Menu

The maximum recommended separation between pulley's center is 15 to 20 multiple of the smaller pulley pitch diameter. The larger the distance between perspective pulley's could resulting in significant differences in belt tension relative to any stretch of the belt.

Positioning mechanism should be considered within the belt tension mechanical assembly, to allow adjustments and help properly set the belts tension. Idler pulleys can be used in the pulley path to minimize belt tension variations.

Equation to Determine Flat Belt Length:

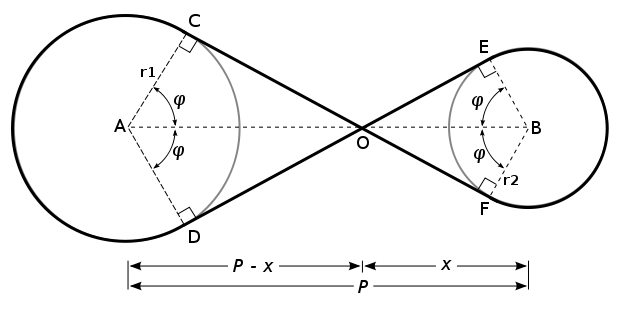

Equation to Determine Crossed Belt Friction Belt Drive

![]()

Crossed Belt Friction Belt Drive Calculator

Where:

L = Length (inches)

C = Center Distance (inches)

D1 = Pitch Diameter of Small Pulley (inches)

D2 = Pitch Diameter of Large Pulley (inches)

When determining the length of a serrated type belt, both equations are to be divided by the belt serration pitch. The serrated belt length should be designed for whole or even number of serrations.